Stainless Steel Corrugated Tube For Heat Exchanger

Stainless Steel Corrugated Tube For Heat Exchanger

Stainless Steel Corrugated Tube is usually used in heat exchange equipment. Compared with ordinary seamless steel pipes, Stainless Steel Corrugated Tube has a larger heat exchange area, smaller tube wall thermal resistance, and excellent heat transfer coefficient, so it is not Stainless Steel Corrugated Tube For Heat Exchanger is a new type of high-efficiency heat exchange tube that replaces the tube and has been widely used in heat exchange equipment.

Stainless Steel Corrugated Tube For Heat Exchanger is a thin-walled tube with large and small arcs continuously tangent and corrugated inside and outside. The three-dimensional movement outside the tube, so the degree of disturbance is more intense, even if the fluid flow rate is very low, it can make it into a turbulent state, and at the same time, the thin tube wall has a small temperature gradient, which greatly reduces the thermal resistance of the tube wall and improves the heat transfer inside and outside the tube. Coefficient, so that the overall heat transfer coefficient is improved.

1.The Main Material(Grade)

TP304, TP304L, TP321, TP316, TP316L, TP310S, TP347H, 2205, 2507, TP904L

Chemical composition of Stainless Steel Corrugated Tube

| Grade | Chemical composition, % | |||||||||||

| C | S | Mn | P | S | Cr | Ni | Nb | Mo | Cu | N | Other | |

| Max | ||||||||||||

| TP304 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 18-20 | 8-11 | |||||

| TP304L | 0.035 | 1.00 | 2.0 | 0.045 | 0.03 | 18-20 | 8-13 | -- | -- | -- | -- | |

| TP321 | 0.08 | 0.75 | 2.00 | 0.045 | 0.03 | 17-19 | 9-12 |

Ti= 5(C+N) 0.70 |

||||

| TP316 | ≤0.08 | 0.75 | 2.00 | 0.045 | 0.03 | 16-18 | 10-14 | 2.0-3.0 | ≤0.10 | |||

| TP316L | 0.04-0.10 | 1.00 | 2.00 | 0.045 | 0.03 | 16-18 | 11-14 | -- | 2.0-3.0 | -- | -- | |

| TP310S | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 24-26 | 19-22 | -- | ≤0.75 | -- | -- | |

| TP347H | 0.04-0.10 | 1.00 | 2.00 | 0.045 | 0.03 | 17-19 | 9-13 | 8*C-1.1 | ||||

| S32205 | 0.030 | 1.0 | 2.0 | 0.03 | 0.02 | 22-23 | 4.5-6.5 | -- | 3.0-3.5 | -- | 0.14-0.2 | |

| TP904L | 0.02 | 1.00 | 2.00 | 0.045 | 0.035 | 19~23 | 23~28 | -- | 4.0~5.0 | 1.0~2.0 | -- | |

2.Stainless steel corrugated heat exchange tube specification series

|

Small outer diameter mm |

Large outer diameter mm |

Crest distance mm |

Weightkg/m |

Heat exchange area m2/m |

|||||||

| 0.6 | 0.7 | 0.8 | 0.9 | 1.0 | 1.1 | 1.2 | 1.5 | ||||

| 16 | 19 | 15 | 0.257 | 0.297 | 0.336 | 0.375 | 0.414 | 0.437 | 0.0572 | ||

| 18 | 22 | 15 | 0.292 | 0.338 | 0.383 | 0.427 | 0.471 | 0.515 | 0.542 | 0.0665 | |

| 18 | 22 | 20 | 0.291 | 0.336 | 0.380 | 0.425 | 0.468 | 0.512 | 0.537 | 0.0658 | |

| 19 | 22 | 20 | 0.306 | 0.357 | 0.394 | 0.439 | 0.485 | 0.531 | 0.576 | 0.0665 | |

| 19 | 25 | 20 | 0.318 | 0.367 | 0.416 | 0.465 | 0.514 | 0.0747 | |||

| 20 | 25 | 20 | 0.332 | 0.383 | 0.436 | 0.485 | 0.535 | 0.585 | 0.635 | 0.0750 | |

| 22 | 25 | 20 | 0.351 | 0.406 | 0.461 | 0.513 | 0.568 | 0.622 | 0.672 | 0.0759 | |

| 25 | 28 | 25 | 0.399 | 0.463 | 0.526 | 0.588 | 0.649 | 0.711 | 0.771 | 0.952 | 0.0852 |

| 25 | 30 | 25 | 0.408 | 0.471 | 0.536 | 0.600 | 0.665 | 0.727 | 0.789 | 0.974 | 0.0902 |

| 25 | 32 | 25 | 0.426 | 0.487 | 0.555 | 0.622 | 0.685 | 0.751 | 0.814 | 0.0957 | |

| 27 | 30 | 25 | 0.440 | 0.510 | 0.576 | 0.645 | 0.714 | 0.778 | 0.846 | 1.045 | 0.0916 |

| 27 | 32 | 25 | 0.445 | 0.516 | 0.586 | 0.654 | 0.722 | 0.790 | 0.858 | 1.060 | 0.0966 |

| 32 | 38 | 30 | 0.527 | 0.610 | 0.691 | 0.774 | 0.850 | 0.929 | 1.007 | 1.247 | 0.1144 |

| 32 | 40 | 30 | 0.537 | 0.624 | 0.710 | 0.796 | 0.880 | 0.965 | 1.049 | 0.1198 | |

| 32 | 42 | 30 | 0.562 | 0.650 | 0.733 | 0.812 | 0.888 | 0.974 | 1.059 | 0.1258 | |

| 38 | 42 | 35 | 0.616 | 0.713 | 0.811 | 0.908 | 1.002 | 1.099 | 1.192 | 0.1275 | |

| 38 | 45 | 40 | 0.631 | 0.732 | 0.833 | 0.931 | 1.025 | 1.123 | 1.217 | 0.1336 | |

| 40 | 50 | 45 | 0.883 | 0.970 | 1.074 | 1.179 | 1.283 | 0.1480 | |||

| 48 | 54 | 50 | 1.151 | 1.276 | 1.401 | 0.1653 | |||||

| 50 | 57 | 50 | 1.282 | 1.487 | 1.532 | 1.892 | 0.1682 | ||||

| 50 | 62 | 50 | 1.367 | 1.501 | 0.1861 | ||||||

3.Maximum allowable working pressure of stainless steel corrugated tube

| Grade | Specification | Temperature ℃ | |||||||

|

Nodal peak outer diameter |

Wall thickness | ≤20 | 100 | 150 | 200 | 250 | 300 | 350 | |

| Allowable pressure Mpa | |||||||||

|

0Cr18Ni9 0Cr18Ni10Ti 0Cr17Ni12Mo2 0Cr19Ni13Mo3 |

32/45 | 0.6 | 2.6/1.9 | 2.4/1.8 | 3.7/1.7 | 2.1/1.6 | 2.1/1.6 | ||

| 0.7 | 3.0/2.3 | 2.9/2.1 | 2.7/2.0 | 2.5/1.8 | 2.4/1.8 | ||||

| 0.8 | 3.4/2.6 | 3.3/2.5 | 3.1/2.3 | 2.9/2.2 | 2.8/2.1 | ||||

| 0.9 | 3.9/2.9 | 3.7/2.8 | 3.5/2.6 | 3.2/2.4 | 3.2/2.4 | ||||

| 1.0 | 4.3/3.3 | 4.1/3.1 | 3.9/2.9 | 3.6/2.7 | 3.5/2.6 | ||||

| 1.1 | -/3.6 | -/3.4 | -/3.2 | -/3.0 | -/2.9 | ||||

| 1.2 | -/3.9 | -/3.7 | -/3.5 | -/3.3 | -/3.2 | ||||

|

00Cr19Ni10 00Cr17Ni14Mo2 00Cr19Ni13Mo3 |

0.6 | 2.4/1.8 | 2.2/1.6 | 2.0/1.5 | 1.9/1.4 | 1.8/1.4 | |||

| 0.7 | 2.8/2.1 | 2.5/1.9 | 2.4/1.8 | 2.2/1.7 | 2.1/1.6 | ||||

| 0.8 | 3.2/2.4 | 2.9/2.2 | 2.7/2.0 | 2.6/1.9 | 2.4/1.8 | ||||

| 0.9 | 3.6/2.7 | 3.3/2.5 | 3.0/2.3 | 2.9/2.2 | 2.7/2.1 | ||||

| 1.0 | 4.0/3.0 | 3.7/2.8 | 3.4/2.5 | 3.2/2.4 | 3.1/2.3 | ||||

| 1.1 | -/3.3 | -/3.0 | -/2.8 | -/2.7 | -/2.5 | ||||

| 1.2 | -/3.6 | -/3.3 | -/3.1 | -/2.9 | -/2.8 | ||||

Note:

1. The blasting pressure safety factor is 8;

2. The allowable pressure of the intermediate temperature can be obtained by interpolation according to the pressure value of this table;

3. The front side of the diagonal line is the allowable pressure value of Φ32 series (including Φ19, Φ22, Φ25, Φ32), and the back of the allowable pressure value of Φ45 series (including Φ38, Φ40, Φ42, Φ44, Φ45).

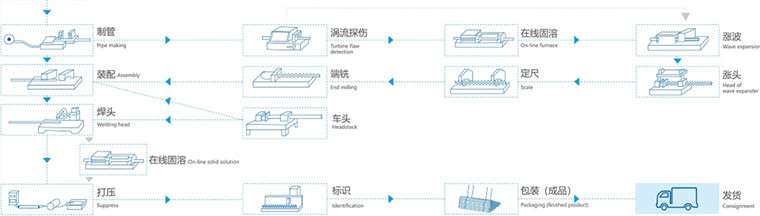

4.Process flow chart of Stainless Steel Corrugated Tube For Heat Exchanger

5.Stainless Steel Corrugated Tube For Heat Exchanger has the following advantages.

(1)The uneven surface of Stainless Steel Corrugated Tube makes the fluid form strong turbulence in the tube, thereby greatly improving the heat transfer coefficient of the inner and outer surfaces of the tube, and the overall heat transfer efficiency of the heat exchanger is increased by 2-3 times than that of the tube type;

(2)Stainless Steel Corrugated Tube is resistant to high temperature and can withstand large temperature and pressure differences

Although the wall of the Stainless Steel Corrugated Tube is very thin (0.6-1.2mm), the special free forming process and unique arc shape greatly improve its pressure-bearing capacity. At the same time, the corrugated tube heat exchanger can adapt to a higher working temperature, up to 350°C. Corrugated pipe is a kind of flexible element with certain thermal compensation ability, good adaptability to large working temperature difference, small thermal stress of equipment, and obvious superiority over ordinary seamless steel pipe.

(3)The corrugated tube has a self-cleaning effect through thermal expansion and contraction, has the performance of not easy to scale, and compensates for the thermal stress caused by the temperature difference;

Heat exchanger fouling, corrosion and blockage have always been a difficult problem to solve, especially when the water quality is poor, the water treatment effect is not good, the gas medium contains impurities or chemical reactions are prone to form fouling substances. The problem is particularly prominent. In the lighter case, the function of the heat exchanger decreases, the working condition deteriorates, the resistance becomes larger, and the energy consumption increases, while the worst case is that the heat exchanger is blocked and cannot operate, so the workload of maintenance, cleaning or renewal of the heat exchanger will also increase. Therefore, the use of Stainless Steel Corrugated Tubes for the tube bundle in the heat exchanger will completely solve this problem.

(4)Due to the compensation function of the Stainless Steel Corrugated Tube, the thermal stress of the tube sheet can be reduced, the tube opening will not be broken and the leakage problem will be caused, and the heat exchanger is safe and durable;

In addition to the above advantages, the corrugated tube produced by Dongyan Energy Conservation has the advantages of strong corrosion resistance, longer life, no pitting, and low price.

(5)Stainless steel corrugated pipe has uniform stress distribution and strong corrosion resistance

Because the stainless steel corrugated tube adopts a unique forming process, the feature of this process is that during the forming process, the deformation is not formed by the forced flow of metal in the mold, but a free-flowing "soft forming" process. Because there is no forced deformation, the forming process will not cause stress concentration, small residual stress, uniform stress distribution, no intercrystalline defects, and strong stress corrosion resistance.

(6)The stainless steel corrugated tube has a long service life and high cost performance.

The corrugated pipe adopts ultra-thin stainless steel material, which on the one hand improves the service life of the product, but also greatly reduces the weight of the product, saves materials, reduces the cost of operation and maintenance, reduces the floor space, and greatly improves the cost-effectiveness of the product. The economic benefits are obvious.

6.Application

Stainless Steel Corrugated Tube For Heat Exchanger has now been widely used in petroleum, chemical industry, power system, heating and heating, etc.

![field:title/]](/uploads/210625/1-210625161916213.jpg)

![field:title/]](/uploads/210820/1-210R0152411C1.jpg)

![field:title/]](/uploads/200227/1-20022G02605963.jpg)

![field:title/]](/uploads/191012/1-191012155K0112.png)

![field:title/]](/uploads/191012/1-191012155ZL36.png)

![field:title/]](/uploads/191012/1-191012155941221.png)

![field:title/]](/uploads/191012/1-191012160101521.png)