G Type Embedded Finned Tube For Heat Exchangers

G Type Embedded Finned Tube

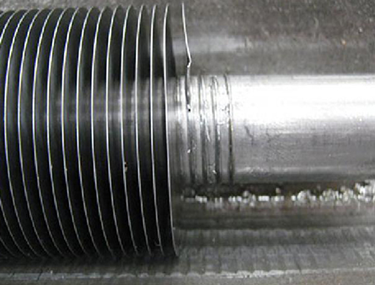

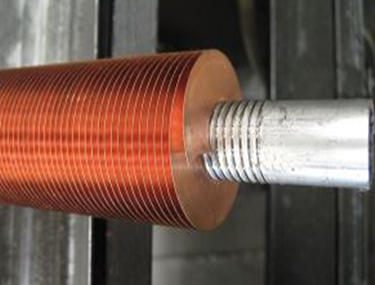

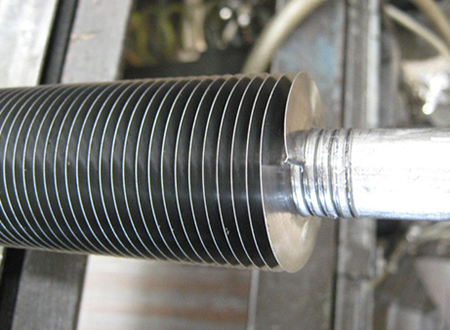

G Type Embedded Finned Tube is that the fin strip is tension wound and placed in the groove cut into the tube with appr, 0.4mm groove depth, then the bottom of the fin is guided into the groove and backfilled with base tube Firmly, finally lock the fins in place by rolling the grooves enclosed in the bottom of the fins. The maximum operating temperature of G Type Embedded Finned Tube can reach 400°C.

G Type Embedded Finned Tube Quick Details:

Core tube material:

1. Carbon steel: A179, A192, SA210 Gr A1/C, A106 Gr B

2. Stainless steel: TP304/304L, TP316/TP316L/316Ti, A789 S31803/S2205

3. Copper: UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10

Fin material:

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

Fin type: Solid plain

Fin Tube Type: G Type Embedded

Outer diameter (OD): 16mm Min~50.8mm max.

Tube length: up to 18,000 mm.

Fin height: 16.5mm max.

Fin thickness: generally 0.4mm~0.6mm

Fin pitch: 2.1mm minimum (12FPI)

Surface Protection: Both bare ends shall be zinc or aluminum metallized by electrospray arc system coating.

Accessories: Tube support boxes, clamps or spacer boxes (materials: aluminium, zinc and stainless steel).

Additional Info

Payment Terms:T/T, LC

Delivery: 15-30 days after payment

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Iron frame packing boxes and the desiccants are put into each package for continental transportation as well. or as required

The case of G Type Embedded Finned Tube

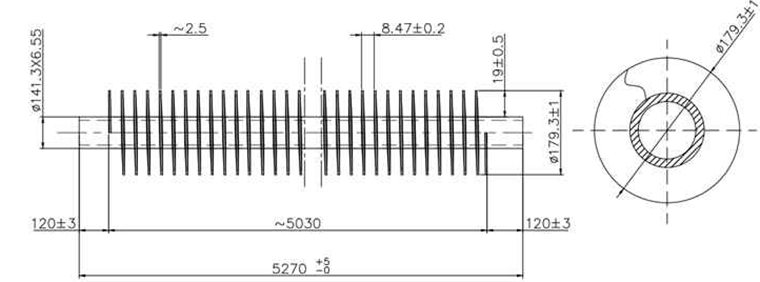

Common Specifications of G Type Embedded Finned Tube

| All dimensions are in Inches and specification upon your requests | |||

| Tube OD | Fin Height | Fin Thickness | Fins per Pitch |

| 5/8 | 3/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 3/4 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 1/4 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 1/2 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

We can customize The case of G Type Embedded Finned Tube according to your drawings

Example:

Manufacturing Process:

G Type Embedded Finned Tube is that the fin strip is tension wound and placed in the groove cut into the tube with appr, 0.4mm groove depth, then the bottom of the fin is guided into the groove and backfilled with base tube Firmly, finally lock the fins in place by rolling the grooves enclosed in the bottom of the fins.

G Type Embedded Finned Tube is combined with two different materials

Core tube material: carbon steel, low alloy steel, stainless steel, brass, copper, copper-nickel alloy, aluminum bronze, nickel alloy.

1. Carbon steel: A179, A192, SA210 Gr A1/C, A106 Gr B

2. Stainless steel: TP304/304L, TP316/TP316L/316Ti, A789 S31803/S2205

3. Copper: UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10

Fin material:

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

Quality Control for G Type Embedded Finned Tube

Inspection and Tests Performed

Chemical Composition inspection,

Mechanical Properties Test(Tensile Strength, Yield Strength, Elongation, Flaring, Flattening, Hardness, Impact Test),

Surface and Dimension Test,

No-destructive Test,

Hydrostatic Test.

Delivery condition:

Tube ends are square cut, free burrs, internally dried and air blown clean, externally coated with varnish at both ends of G-Fin Embedded Finned Tube.

Acceptance Criteria

API Standard 661 (Air-Cooled Heat Exchangers for General Refinery Service) or Delivery Conditions (TDC).

Features of G Type Finned Tube for Heat Exchanger

1. High heat transfer performance and small contact thermal resistance.

2. The contact area between the fin and the tube is large, and the fit is tight and reliable.

3. Good resistance to atmospheric corrosion and stable long-term use

4. Can be used for a long time at high temperature

Application of G Type Finned Tube for Heat Exchanger

●Petroleum, chemical and petrochemical industries

●Natural gas treatment

●Steel industry: blast furnace and converter system

Power generation: exhaust gas from steam turbine condenses, condensate water contact circulation cooling condensate, fossil and nuclear power plants

● Air conditioning (Freon, ammonia, propane)

●Waste incineration equipment

●Compressor cooler, etc.

Maximum operating temperature of KL Type Finned Tube up to 400°C

Packaging picture of G Type Finned Tube

![field:title/]](/uploads/220318/1-22031QI359256.jpg)

![field:title/]](/uploads/220318/1-22031QG3434U.png)

![field:title/]](/uploads/220318/1-22031QA14I91.png)

![field:title/]](/uploads/220318/1-22031Q62510194.png)

![field:title/]](/uploads/220318/1-22031Q60ZJE.jpg)

![field:title/]](/uploads/220317/1-22031G620064D.jpg)

![field:title/]](/uploads/220317/1-22031G60KT56.png)